ABOUT OUR MIRRORS

Mirrors exist in space and are dependent on it through reflections; they also create a new space into which our world permeates. In the direct confrontation with such an object, we will perceive our own image reflected in it – in the surroundings – with the surroundings – in which we exist here and now. A mirror attracts and provokes us to take a look at ourselves in a direct way, gives an opportunity for a reflective look – a paused glimpse… a question mark… a brooding thought.

It is an object linked to our consciousness and a perfect tool for self-reflection. Despite being an everyday object, it holds a more profound meaning beyond its practical purpose. Let’s add how it morphs into being, and we will receive an utterly extraordinary object.

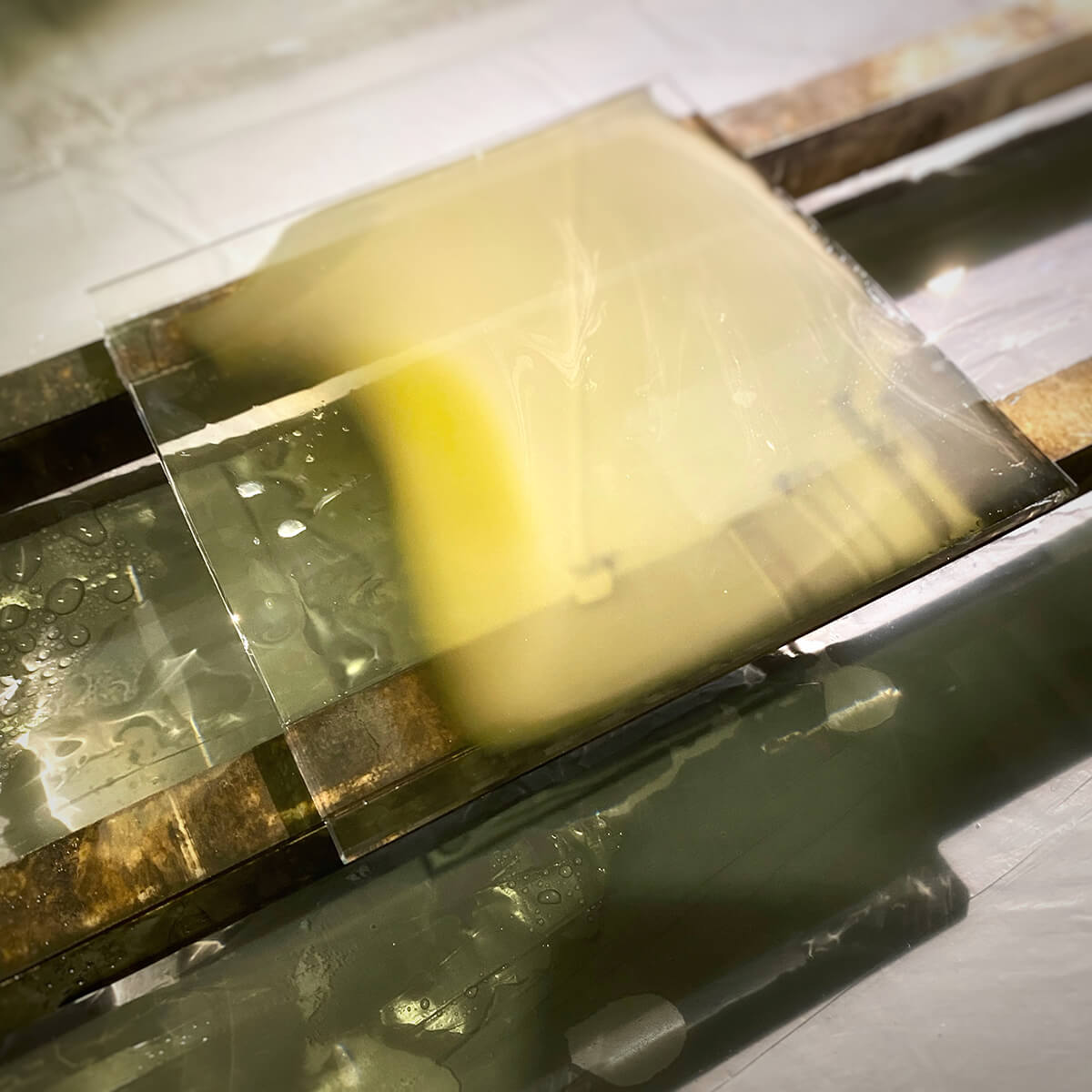

To create our mirrors, we start with a transparent glass pane which we coat with a layer of light-reflecting silver, gold, or copper. We use two techniques to make mirrors: silver pouring and reverse gilding. Both techniques originated in antiquity and have been developed and refined over the centuries.

In 1835, the German chemist Justus von Liebig came up with the silver pouring technique. This technique involves coating the glass with a solution that contains silver, which then settles on the surface of the glass to create a reflective layer. This method allows for the individual development of a mirror surface, providing a unique opportunity to explore interesting contexts that go beyond formal designs. The versatility of this technique often encourages experimentation.

In the realm of decorative art, the process of gilding glass with metal leaves made of gold and other metals is commonly combined with the techniques of painting or engraving on glass, which is known as verre églomisé in French. This method was frequently used to create shop signs or to inscribe golden letters on shop windows, which are now regaining popularity. Currently, gilding on glass is experiencing a renaissance.

In our workshop, we use metal leaves from the Florentine forge of Giusto Manetti Battiloro. This forge has been producing gold leaf since 1820, and our 8 x 8 cm gold leaf comes in booklets of 25 leaves, with each leaf being covered with tissue paper. Our mirrors are created with 24-carat gold leaves, which are 16th-thick, amounting to 0.05 μm. The copper leaves are 12 x 12 cm, and their thickness is 3 μm. Similar to gold leaves, they are also placed in booklets.

As the material is highly delicate, the hand application of gold leaf requires great expertise, precision, and even breath control. It is not just a demanding and time-consuming technique but can also be stressful due to the high value of the precious metal.

Our mirrors reflect the beauty of the materials used and the skilled craftsmanship that goes into their creation. They are made with care, in quiet concentration or with the accompaniment of music. But above all, they are made with PASSION.